à¤à¤¾à¤¸à¥à¤ à¤à¤¯à¤°à¤¨ वॠबà¥à¤²à¥à¤ पà¥à¤²à¥

Price 250.0 आईएनआर/ Unit

MOQ : 100 टुकड़ाs

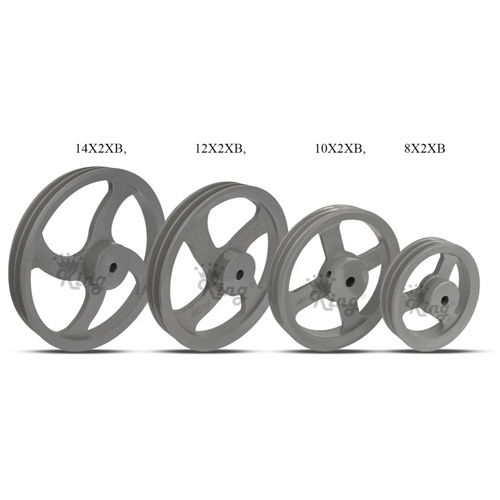

à¤à¤¾à¤¸à¥à¤ à¤à¤¯à¤°à¤¨ वॠबà¥à¤²à¥à¤ पà¥à¤²à¥ Specification

- उपयोग

- औद्योगिक

- मटेरियल

- साइज

- विभिन्न उपलब्ध

- प्रॉडक्ट टाइप

- चरखी

- वज़न

- उत्पाद के आकार के अनुसार भिन्न किलोग्राम (kg)

- रंग

- स्लेटी

à¤à¤¾à¤¸à¥à¤ à¤à¤¯à¤°à¤¨ वॠबà¥à¤²à¥à¤ पà¥à¤²à¥ Trade Information

- Minimum Order Quantity

- 100 टुकड़ाs

- भुगतान की शर्तें

- आपूर्ति की क्षमता

- 5000 प्रति महीने

- डिलीवरी का समय

- 7 दिन

- नमूना उपलब्ध

- No

- नमूना नीति

- पैकेजिंग का विवरण

- We are doing packing in gunny bag along with cartoon box packing will giving always.

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

- प्रमाणपत्र

- AN ISO 9001 : 2015 CERTIFIED COMPANY

About à¤à¤¾à¤¸à¥à¤ à¤à¤¯à¤°à¤¨ वॠबà¥à¤²à¥à¤ पà¥à¤²à¥

The pulley has a groove or several grooves that are shaped like a "V," designed to fit the corresponding V-shaped sides of the belt. This design ensures a secure grip between the pulley and the belt, minimizing slippage and improving power transmission efficiency.Precision Engineering for Reliable Performance

Each Cast Iron V Belt Pulley undergoes precision machining to ensure optimal fit and smooth operation. The balanced construction minimizes vibration and wear, which extends the service life and enhances efficiency in heavy-duty industrial environments.

Versatile Configurations to Meet Industrial Demands

With diameters ranging from 2 to 60 inches and groove counts from 1 to 10, these pulleys accommodate a wide spectrum of power transmission requirements. Their adaptable mounting systemstaper lock or standardsimplify installation in various types of machinery.

FAQs of Cast Iron V Belt Pulley:

Q: How do I select the appropriate size of Cast Iron V Belt Pulley for my machinery?

A: You should base your selection on the required power transmission capacity, shaft size, and number of grooves needed. Since pulleys are available from 2 to 60 inches in diameter and offer 1 to 10 grooves, reviewing your machines specifications will help determine the right fit.Q: What is the installation process for the Cast Iron V Belt Pulley?

A: Installation involves aligning the pulley on the shaft using either the taper lock or standard mounting method. Precision machining ensures the bore fits securely; carefully follow the manufacturers guidelines to ensure correct alignment and secure locking.Q: Where can these pulleys be used?

A: Cast Iron V Belt Pulleys are designed for industrial power transmission. They are commonly applied in industrial machinery, manufacturing plants, and heavy equipment where mechanical strength and reliability are essential.Q: When is it beneficial to use a cast iron pulley over other materials?

A: Cast iron pulleys are ideal when heavy-duty performance, high strength, and long service life are required. Compared to lighter materials, cast iron offers superior durability, especially in high-load or continuous operation settings.Q: What advantages does balanced construction provide in these pulleys?

A: Balanced construction reduces vibration and operational noise, which prolongs the lifespan of both the pulley and associated machinery. This balance also contributes to smoother, more efficient power transmission.Q: How does the precision-machined bore improve pulley performance?

A: A precision-machined bore ensures an exact fit on the shaft, reducing slip and wear. This precise fit enhances the pulleys operational stability and decreases maintenance requirements.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in वी बेल्ट स्टेप पुली Category

वी स्टेप पुली

उपयोग : औद्योगिक

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 100

माप की इकाई : यूनिट/यूनिट

प्रॉडक्ट टाइप : चरखी

साइज : विभिन्न उपलब्ध

वी बेल्ट पुली

उपयोग : औद्योगिक

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 100

माप की इकाई : यूनिट/यूनिट

प्रॉडक्ट टाइप : चरखी

साइज : विभिन्न उपलब्ध

GST : 24AAPFB6527N1ZZ

फ़ोन :07971191182

श्री केतन पटेल

(बिक्री एवं विपणन प्रमुख)

मोबाइल :07971191182

श्री केतन पटेल

(बिक्री एवं विपणन प्रमुख)

मोबाइल :07971191182

|

B N Industries

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें